In recent years, 3D printing has emerged as a revolutionary technology with the potential to transform the landscape of design and manufacturing. From rapid prototyping to intricate customization, the power of 3D printing is reshaping industries and driving innovation like never before.

Table of Contents:

We invite you to read: “EXPLORING QUANTUM COMPUTING: A NEW ERA OF COMPUTING POWER”

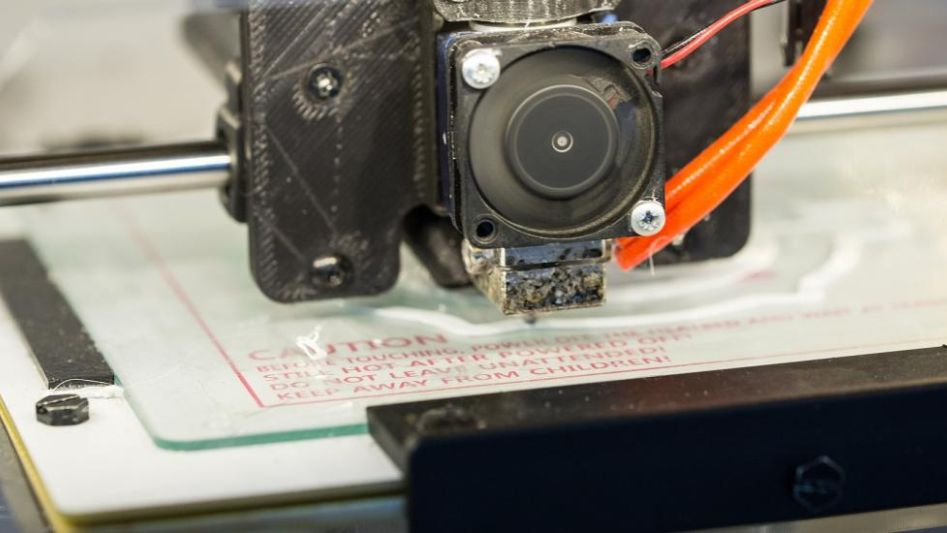

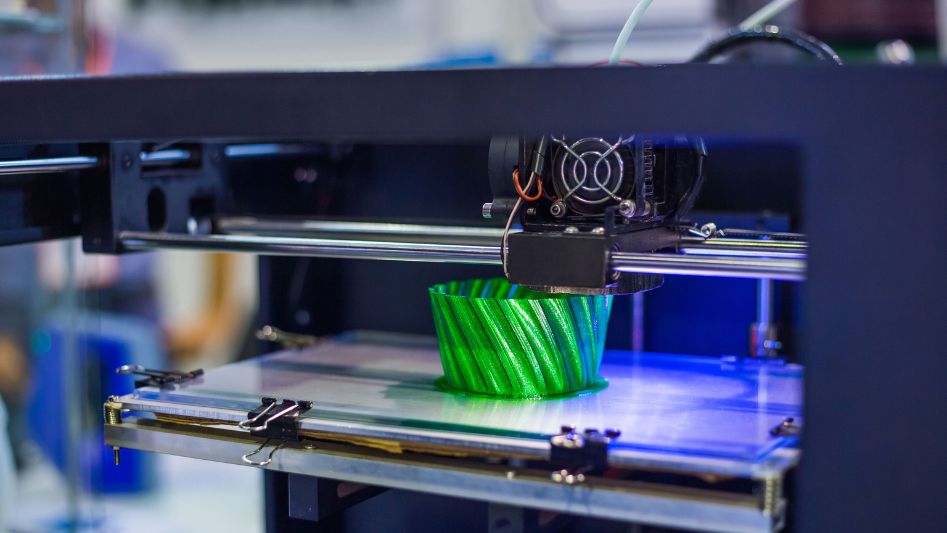

The Process Behind 3D Printing

At its core, 3D printing, also known as additive manufacturing, involves creating three-dimensional objects by layering material on top of each other. Unlike traditional subtractive manufacturing methods that involve cutting and shaping raw materials, 3D printing builds objects layer by layer, making it highly efficient and precise.

Unleashing Creativity and Customization

One of the most significant advantages of 3D printing is its ability to unleash creativity and enable unparalleled customization. Designers and engineers can now bring their ideas to life with ease, pushing the boundaries of what’s possible in product design. From personalized consumer products to complex industrial components, 3D printing opens doors to infinite possibilities.

Accelerating Product Development

In traditional manufacturing, developing a prototype or a new product can be a time-consuming and costly process. With 3D printing, this has changed dramatically. Prototypes can now be designed, tested, and refined in a fraction of the time, allowing companies to accelerate their product development cycles. This speed to market not only saves time and money but also gives businesses a competitive edge in the fast-paced global market.

We invite you to read: “THE POWER OF BIG DATA: UNLOCKING INSIGHTS FOR BUSINESSES”

Sustainability and Waste Reduction

Sustainability is a pressing concern in today’s world, and 3D printing is making significant strides in this area as well. Unlike conventional manufacturing methods that often generate substantial waste, 3D printing is an additive process that produces little to no waste. It enables manufacturers to optimize material usage and reduce their environmental footprint, making it a greener and more sustainable option.

Empowering Healthcare and Biotechnology

The impact of 3D printing extends beyond the realms of design and manufacturing; it has also made its way into the healthcare and biotechnology sectors. 3D printing has been used to create medical implants, prosthetics, and even human organs, revolutionizing the healthcare industry and improving the quality of life for many patients worldwide.

Challenges and Opportunities Ahead

While 3D printing holds immense promise, it’s not without its challenges. The technology is still evolving, and there are hurdles to overcome in terms of material limitations, scalability, and intellectual property concerns. However, with each passing day, researchers, engineers, and innovators are working tirelessly to address these challenges and unlock new opportunities for 3D printing.

We invite you to read: “GAMING TECHNOLOGY: WHERE ENTERTAINMENT MEETS CUTTING-EDGE INNOVATION”

Conclusion

3D printing is a transformative force that is reshaping the world of design and manufacturing. Its ability to drive creativity, enable customization, accelerate product development, and promote sustainability makes it a game-changer across various industries. As the technology continues to advance, we can expect even more groundbreaking applications and a brighter, more efficient future for design and manufacturing.

FAQs

What is 3D printing?

3D printing, also known as additive manufacturing, is a cutting-edge technology that constructs three-dimensional objects layer by layer, revolutionizing design and manufacturing processes.

How does 3D printing work?

3D printing works by layering material on top of each other based on a digital model, creating precise and intricate objects with unparalleled customization.

What are the benefits of 3D printing?

3D printing unleashes creativity, accelerates product development, reduces waste, and finds applications in diverse industries, from healthcare to consumer products.

Can 3D printing be sustainable?

Yes, 3D printing is more sustainable compared to traditional manufacturing, as it generates little to no waste and optimizes material usage.

You May Also Like

- THE IMPACT OF 5G TECHNOLOGY: FASTER SPEEDS, ENHANCED CONNECTIVITY

- THE FUTURE OF TECHNOLOGY: 10 INNOVATIONS THAT WILL TRANSFORM OUR LIVES

- THE ROBOT TAKEOVER: WILL MACHINES REPLACE HUMANS?

- FROM FICTION TO REALITY: HOW AI IS RESHAPING OUR DAILY LIVES

- 10 MIND-BLOWING WAYS IOT IS TRANSFORMING INDUSTRIES

Recent Comments